In this article, we will explore a new invention that has the potential to end glasses fog.

The new invention is a transparent coating applied to the glasses lens and prevents fog from happening. However, the gold-based transparent coating prevents glasses fog by reducing the surface tension of water droplets on lenses. This means that when water droplets come into contact with the surface of the lens, they don’t form a layer of condensation on it.

Foggy glasses have been a problem for a long time. Since the invention of contact lenses, people who wear glasses have had no choice but to live with the constant fog. But that is about to change.

Evolus is developing a new type of coating that can be applied to glass, much like an invisible film. It’s made of gold particles and completely transparent, so you can’t tell it’s there! This coating will make all glass surfaces resistant to fog, condensation, and sweat stains.

Absorbing a Large Proportion of Infrared Radiation

The new coating is unique in that it selectively absorbs solar light. However, the infrared spectrum contains half of the energy from sunshine, while the visible and UV spectrums include the other half. Iwan Hächler, an ETH doctorate student who was instrumental in the research, notes that “our coating absorbs a considerable amount of the infrared light, which causes it to heat up – by as much as 8 degrees Celsius.” The coating is transparent because it only absorbs a small amount of energy in the visual spectrum.

How does the gold coating work?

The gold-based transparent coating is a solution that works on any glass surface. It can repel fog and other condensation, making glasses fog-free for the rest of the time. Moreover, it can be applied to new glasses or customized with logos and company names.

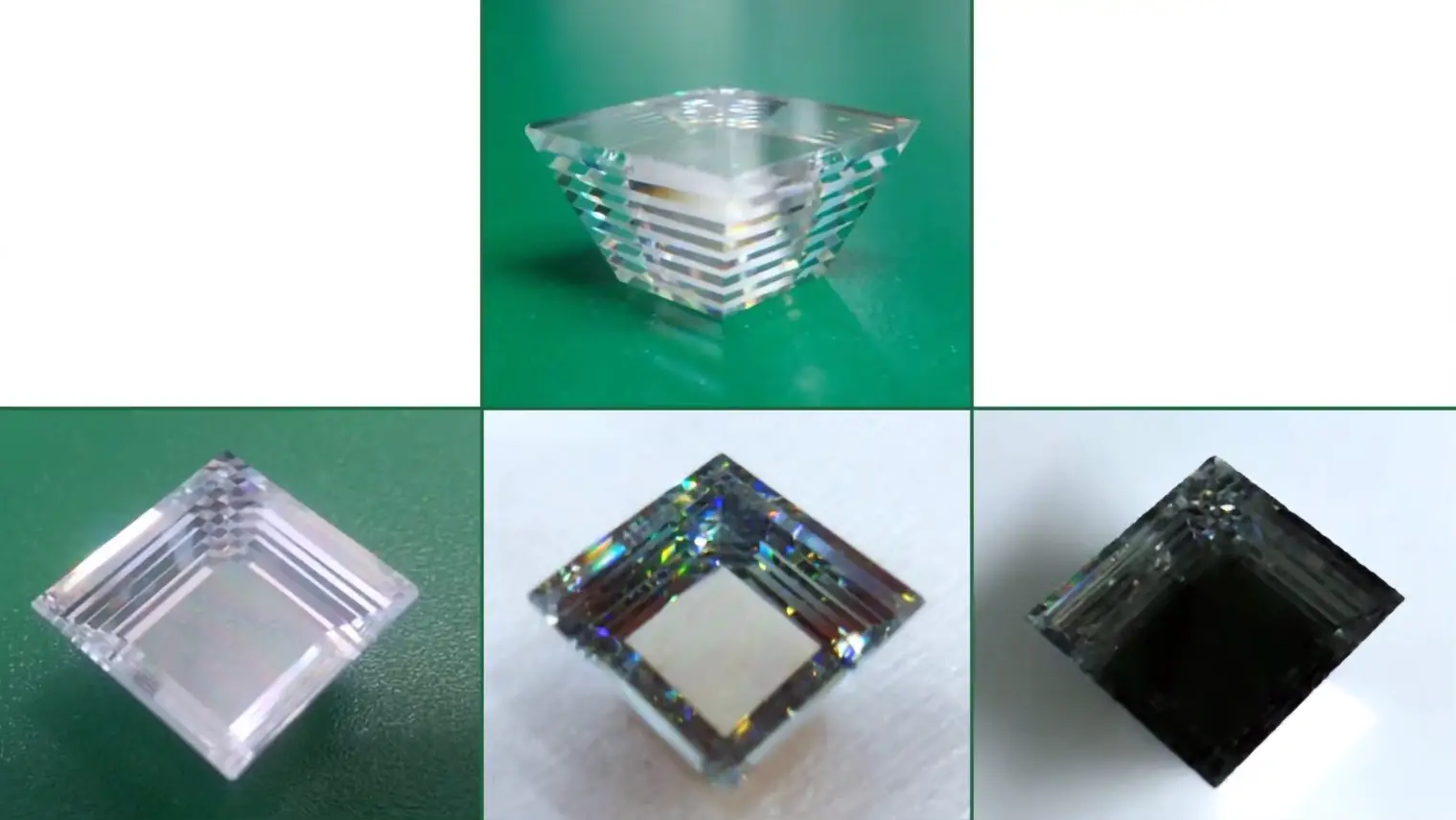

This gold-based transparent coating will end glasses fog forever by preventing the formation of condensation on glass surfaces everywhere you go. The coating is so thin it’s barely detectable to the eye. It is also only visible when looking straight on at the surface. Also, the coating is so thin that it’s barely detectable to the eye.

The concept of a self-cleaning lens seemed like science fiction as recently as a few years ago, but with improved developments in nanotechnology and new coatings, we may be seeing this product on store shelves sooner rather than later. This gold-based transparent coating will end glasses fog forever.

Foggy lenses are the bane of any elegist’s existence – and can lead to some very dissatisfied customers, not to mention expensive replacement lenses for eyeglasses, who have to provide new lenses all too often because their customers are unable to see what they’re doing by looking through a foggy lens while they’re getting their exam. Fogless glasses were first introduced in 1980,

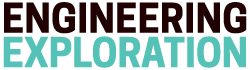

There are three layers of coatings on the glass: a transparent layer, an anti-reflective coating, and a reflective film. The transparent layer blocks infrared light and prevents lenses from fogging up. Moreover, the anti-reflective layer eliminates reflections that can interfere with vision. And the reflective film helps keep the glasses clean and safe by repelling water droplets.

Compared to Current Anti-Fog Applications, Anti-Fog Gold Coating

The project’s long-term goal is to provide the military with a transparent coating that can be applied to various equipment, including gun sights, binoculars, and night vision goggles.

The anti-fog gold coating is applied by a thin layer of gold on top of the surface. This new application for gold is different from existing anti-fog applications like nanocoatings and coatings that use other metals, such as copper or aluminum, as they are not transparent.

The anti-fog properties are achieved due to the high index of refraction of gold which creates an interference pattern (a series of waves) between incoming light waves and outgoing light waves, thereby diffusing the light waves so the viewer can see through it.

Therefore, the anti-fog gold coating is an exciting new invention that could replace the traditional anti-fog application. These coatings aim to produce a layer of molecules that will cling to the surface and prevent condensation from forming.

A major concern with the coatings is that they are too new, and there are no known long-term studies on how they perform compared with traditional anti-fog applications.

Gold-Plated But Not Prohibitively Expensive

They also say that, even though they use a natural source of power (sunlight). Their coating is made using standard, easy-to-scale-up methods and can be easily spread over large areas at a low cost. But since the coating is made of pure gold, would it be possible to sell glasses and windshield fog covers with the same material?

When we asked Haechler about this, he said, “Since the gold layer is only 5 nm thick, it only needs a small amount of gold.” Per square meter of material, there would be 100 mg of gold. If a pair of glasses is about 2×15 cm2, it will take about 0.3 mg of gold to make a pair of glasses. This means that a pair of glasses will cost about 0.017 USD worth of gold.

So, yes, the coating is not too expensive. The only problem with this product is that it needs a certain amount of light to work, even though it can work with very little sunlight. The researchers have already put in for a patent and are now waiting for it to be approved. We hope that this groundbreaking product will be on the market soon.

Final Verdict:

The coating contributes significantly to the temperature increase. It continues to perform well even when cloudy conditions are present. Moreover, this effect manifests in an excellent anti-fogging and defogging performance, equating to a four-fold improvement in fog prevention and a three-fold improvement in fog removal compared with that of an uncoated surface,” said the researcher.

‘It was an extraordinarily exciting moment to watch that the coating reliably performs under demanding, real-world outdoor settings,’ said the researcher.