What is desalination?

Desalination is a method of water filtering used to rid saltwater of minerals and other impurities. Saline water is converted to use water for agriculture and drinking through desalination. Desalination systems are used in homes, yachts, hotels, resorts with beachfront locations, and various commercial and industrial settings.

Only a tiny portion of the world’s population relies on desalination plants to produce clean drinking water. Organizations worldwide anticipate an increase in those numbers as available supplies of drinkable water decrease. Currently, third-world nations with coasts tend to have populations that depend on desalination filtration systems.

Fluorine Nanostructures

Globally, there is a rising issue of water scarcity. The process of desalinating seawater to provide drinking water is well-established, although it has high energy expenditures. For the first time, researchers successfully remove salt from water using fluorine-based nanostructures (Science, “Ultrafast water permeation through nanochannels with a densely fluorous interior surface”).

These fluorous nanochannels function more quickly, use less pressure and energy, and better filter than the present desalination techniques.

If you’ve ever used a nonstick frying pan with a Teflon coating, you’ve probably seen how readily wet ingredients move around it. This occurs because fluorine, a light element that naturally repels water or is hydrophobic, is a fundamental ingredient in Teflon. Teflon can also be used to line pipes, which can increase water flow.

Such behavior caught the attention of Associate Professor Yoshimitsu Itoh from the Department of Chemistry and Biotechnology at the University of Tokyo and his team. It inspired them to explore how pipes or channels made from fluorine might operate on a very different scale, the nanoscale. The researchers produced membranes by forming tubes out of many fluorous rings stacked on one another.

They created a cell membrane by enclosing the side of the tubes by the side in a water-tight layer of lipid molecules. While salt molecules are not welcome, water molecules are. Fluorine repels negatively charged ions, such as the chlorine in salt, at the nanoscale (NaCl). In addition to dissolving water molecule clumps that may otherwise prevent the liquid from flowing as freely as possible, it has electric characteristics.

“We were interested in seeing how well a fluorous nanochannel could filter specific substances, such as salt and water. We also determined that it was worthwhile to spend the time and effort making a working sample after running several intricate computer simulations”, said Itoh. “At the moment, there are two main methods for desalinating water: thermally, which uses heat to evaporate seawater so that it condenses as pure water, or by reverse osmosis, which utilizes pressure to push water through a membrane that prevents salt from re-entering the water. Both techniques consume a lot of energy, but according to our testing, fluorous nanochannels use less energy and have additional advantages.”

Scientists produced test filtering membranes by chemically creating nanoscopic fluorine rings stacked and implanted in an otherwise impermeable lipid layer, analogous to the organic components that constitute cell walls. They produced several test samples with nano rings that ranged in size from one to two nanometers. A human hair is roughly 100,000 nanometers wide as a point of comparison.

Itoh and their colleagues monitored the number of chlorine ions, one of the two main components of salt (the other being sodium), on either side of the test membrane to evaluate the performance of their membranes.

“Seeing the results in person was incredibly exciting. The smaller of our test channels completely rejected entering salt molecules, and even the bigger channels outperformed conventional carbon nanotube filters and other desalination methods, according to Itoh. “How quickly the process took place was what caught me off guard. Our sample operated 2,400 times faster than experimental carbon nanotube-based desalination devices and several thousand times faster than ordinary industrial systems.”

We now create our materials relatively energy-intensively, but we plan to make improvements in this area in the coming years of study. Additionally, according to Itoh, the overall cost of energy will be far lower than with the present methods because of the membranes’ long lifespan and low operating expenses. “Of course, scaling this up is one of the following stages we want to do. Our test samples were single nanochannels, but with the aid of other experts in a few years, we want to develop a membrane about 1 meter wide. We’re investigating if comparable membranes could be used to minimize carbon dioxide or other undesired waste products emitted by industry in addition to these manufacturing-related concerns.”

The team’s fluorine-based water desalination membranes are faster, more efficient, consume less energy, and are also designed to be very user-friendly.

Other ways of desalination technologies.

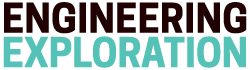

Multistage flash distillation

The most well-established desalting method, distillation, routinely employs MSF technology for seawater desalination. Thermal desalination techniques are utilized for “dual-purpose” (electric power and potable water production) applications, and thermal procedures are employed for applications where RO or electrodialysis reversal is not appropriate. Over 40% of the global desalinated water production capacity comes from MSF units, which are widely used. MSF and RO desalination plants, respectively, take about 40% of the desalination market in North Africa.

Multiple-effect distillation

The multiple-effect distillation method can be used in various settings; for instance, in the 1960s, desalination was a hot topic in modest MED facilities with a 500 m3/day maximum capacity. Ongoing technological advancements cause a rise in unit production capacity. 8 to 16 phases are typically recognized as a standard number of stages.

Vapor-compression

On a small to medium scale, vapor-compression distillation technology is frequently used in seawater desalination plants. Mechanical vapor compression (MVC) is often powered by electricity, and thermal vapor compression is the two available VC technique (TVC). Vapor-compression facilities have been constructed in several arrangements.

Electrodialysis and electrodialysis reversal

Although the “ion exchange” treatment procedure and the electrodialysis desalination process are somewhat similar, the latter use cation and anion-selective membranes to separate charged ions. The electrodialysis reversal (ED) process has been improved by regular automatic polarity reversal, which slows down the fouling process.

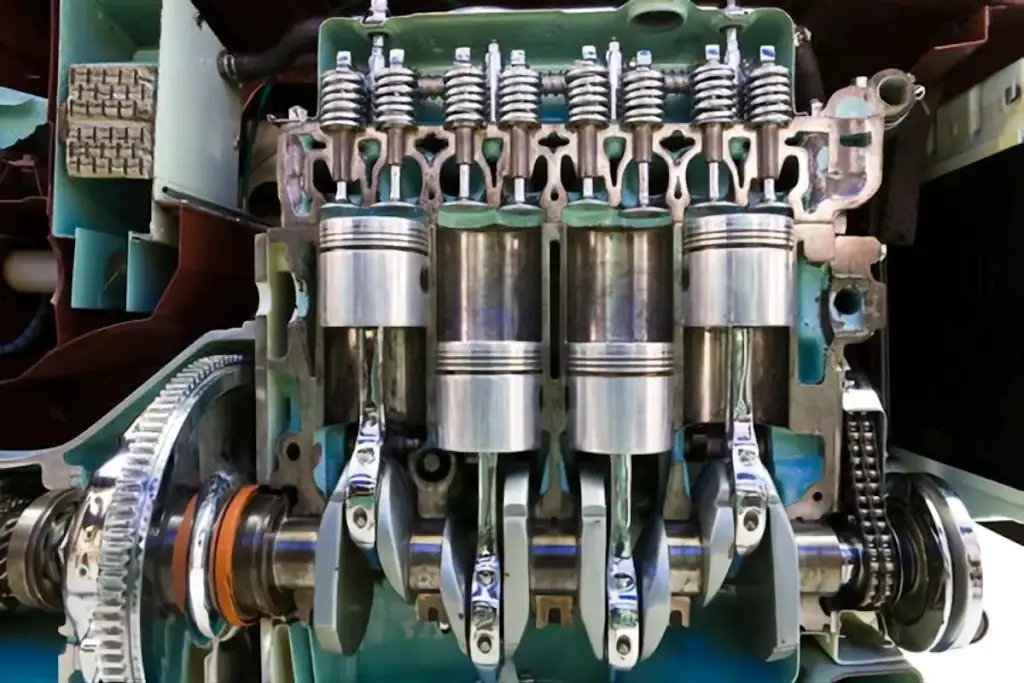

Reverse osmosis

The ultimate filtering method is reverse osmosis (RO) membrane, often referred to as hyperfiltration. Removing microscopic debris and dissolved organic matter is possible with reverse osmosis. Additionally, it is used to clean other fluids, such as glycol and ethanol, by rejecting extra ions and impurities that would otherwise flow through the membrane. Commonly, reverse osmosis is used to treat water. Rever osmosis is used to create water that adheres to the standards set forth.

Nanofiltration

A membrane with pore sizes between 0.5 and 2 nm and operating pressures between 5 and 40 bars is used to perform nanofiltration. Solutions containing organic compounds, carbohydrates, and multivalent salts are treated with NF. Charged nanofiltration membranes reject ions like phosphate or sulfate with a negative charge. According to the form and size of the molecule, a non-charged nanofiltration membrane rejects dissolved matter; nevertheless, for positively charged ions, the rejection is influenced by the membrane charge and by the membrane fouling mechanism.

Membrane distillation

Membrane distillation is a technique for desalinating water using a membrane that is currently only used in limited commercial applications. Membrane distillation combines distillation and RO that uses a hydrophobic synthetic membrane to allow water vapor to diffuse between the pores while blocking the solution. The pressure differential is the difference in the liquid’s vapor pressure as it passes through the membrane.

With the help of membrane distillation, water from a brine solution is turned into vapor and condensed into clear condensate on the chilled side of the membrane.

Forward osmosis

A salt concentration gradient (osmotic pressure) acts as the driving force through the membrane in the relatively new commercial process of forward osmosis, which is used to desalt water. If or when the feed, such as seawater, is present on one side of the membrane, the higher osmotic pressure “pull” (reusable) solution is on the other side of the membrane. Without an external pressure to push through the membrane, the water from the feed solution will naturally migrate to the draw solution. The diluted mixture is then processed to separate the draw solution from the finished product.