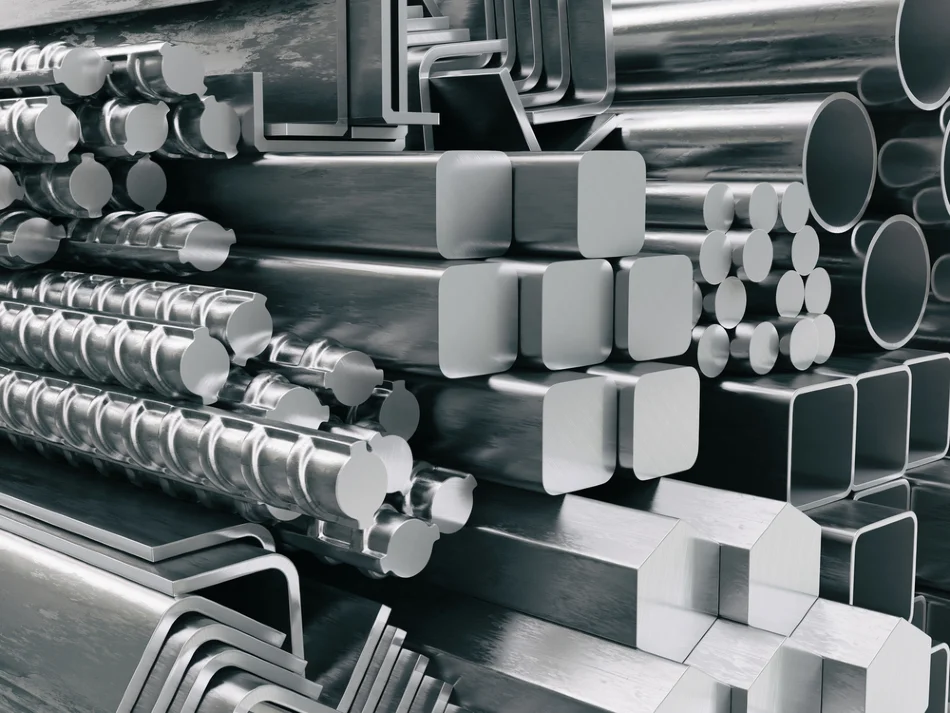

What Is stainless steel?

Stainless steel is an iron alloy that doesn’t rust or break down easily. It has at least 11% chromium and may also have carbon, other nonmetals, and metals to get different desired properties. Because stainless steel has chromium in it, it doesn’t rust because chromium forms a passive film that can protect the material and heal itself when oxygen is present. in this article we will talk about Stainless steel Types, Grades, and Uses.

Common additives include In stainless steel.

- Nickel

- Carbon

- Manganese

- Molybdenum

- Nitrogen

- Sulfur

- Copper

- Silicon

The exact composition of the alloy is rigorously measured and evaluated during the alloying process to ensure that the steel exhibits the desired qualities. Common reasons for adding additional metals and gases to a stainless steel alloy include:

- Increased corrosion resistance

- High-temperature resistance

- Low-temperature resistance

- Improved strength

- Improved weldability

- Improved formability

- Control of magnetism

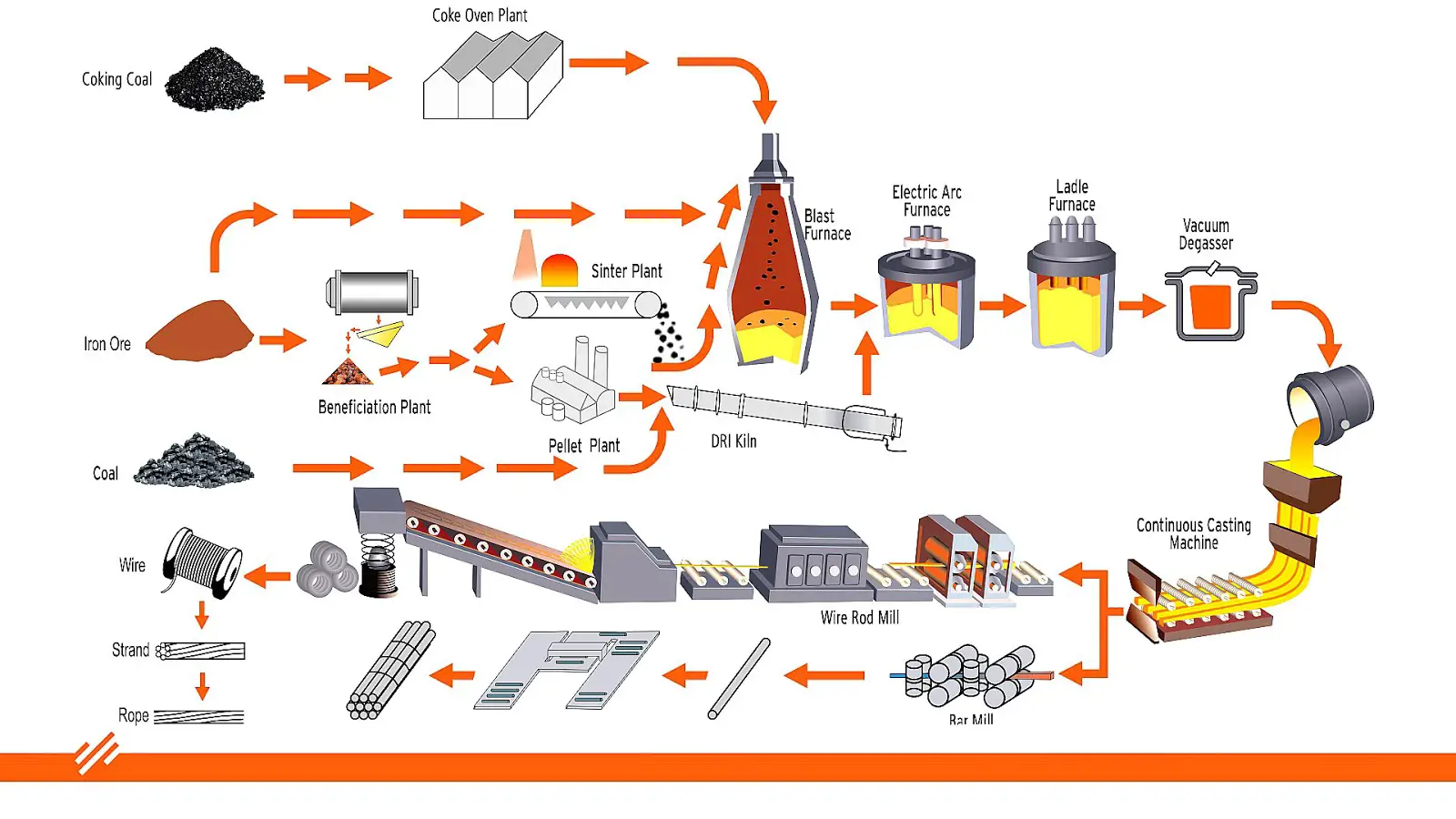

What are the 4 Types of Stainless Steel

Stainless steels are grouped based on how their metal structure changes when they cool down from high temperatures. The four main kinds of stainless steel are:

- Duplex Stainless Steel

- Austenitic Stainless Steel

- Ferritic Stainless Steel

- Martensitic Stainless Stee

Duplex Stainless Steel

The duplex structure uses the same amount of ferrite and austenite. The amount of chromium ranges from 18 to 28%, and the amount of nickel ranges from 4.5 to 8%. Most grades also contain Molybdenum.

Features:

- High resistance to stress corrosion cracking

- Increased level of passivity

- Good weldability and formability

- Higher tensile strength and yield strength than austenitic and ferritic grades

Properties of Duplex Steel

- High resistance to typical surface corrosion and crack corrosion usually happens when parts touch each other.

- It has a lot of strength and is one of the strongest steel. It is hard to break from wear and tear or corrosion under stress.

- Magnetism

- Tensile strength that is much higher than standard steel

- Other types of steel, like austenitic, have a limit on how much they can stretch.

- Very strong, even more than ferritic steels.

- Low melting point.

- The hardness can’t be made harder by heat treatment. Works and welds better than ferritic steels but not as well as austenitic steels.

Austenitic Stainless Steel

Austenitic stainless steel has 18% chromium and 8% nickel as its main ingredients. Austenitic grades are the most common and comprise more than 70% of all production. Type 304 is the most common of these grades. The name comes from the fact that at room temperature, they have a single phase of austenitic metal, which is stable.

Features

- Easy to weld

- High flexibility

- Good resistance to corrosion

- Can handle high temperatures, such as [310°C to 1100°C].

- It can be used at low temperatures, including in cryogenics.

- Is non-magnetic

Properties Of Austenitic Stainless Steel

- Non-magnetic when annealed

- Rapidly work harden with cold work

- Not hardenable by heat treatment

- Ductile and readily formable

- Excellent weldability

- Hygienic with excellent cleanability

- Good performance at high temperatures

- Excellent performance at low temperatures

Ferritic Stainless Steel

Ferritic stainless steel is the second most used type after austenitic stainless steel. They contain deficient levels of carbon and high amounts of chromium but little or no nickel and are known for their flexibility, corrosion resistance, and magnetic properties.

They have a body-centered cubic structure and cannot be hardened by heat treatment but can be cold worked and softened by annealing.

The 400 series describes ferritic stainless steels., which are further classified into five groups depending on their composition and use. Ferritic stainless steels were made early but weren’t widely used until the 1980s.

That’s when they became an excellent alternative to austenitic stainless steels, which were more expensive because they had a nickel.

Properties Of Ferritic Stainless Steel

- Steel That Doesn’t Rust Under Stress Cracking

- Stainless Grades Which Have Good Ductility And Formability

- Types Of Stainless Exhibiting Low Thermal Expansion

- Stainless Is Known To Have High Thermal Conductivity

- Stainless Steel With High Oxidation Resistance

Martensitic stainless steel

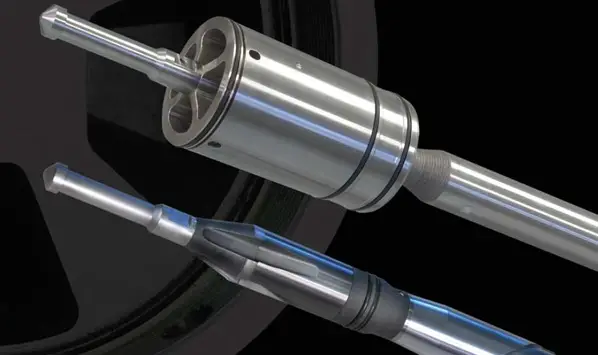

Martensitic steel was developed primarily to meet hardness, high strength, wear resistance, and corrosion resistance requirements. They are also ferromagnetic, meaning they can retain their magnetic properties even after removing the magnetic field.

They can be made harder than ferritic and austenitic stainless steel by heating them. But because of the relatively low amount of chromium, martensitic stainless steels are not as resistant to corrosion as ferritic or austenitic stainless steels.

Properties Of Martensitic stainless steel

- Typical martensitic grades have less corrosion resistance than other types of stainless steel.

- Suitable for making parts and components that are resistant to germs, like medical scalpels and internal clamps.

- Its high hardness, toughness, and corrosion resistance make it an excellent material for use in engineering.

- Most of the time, it is used to make mechanical valves and pumps.

- Suitable For Heat Treatment

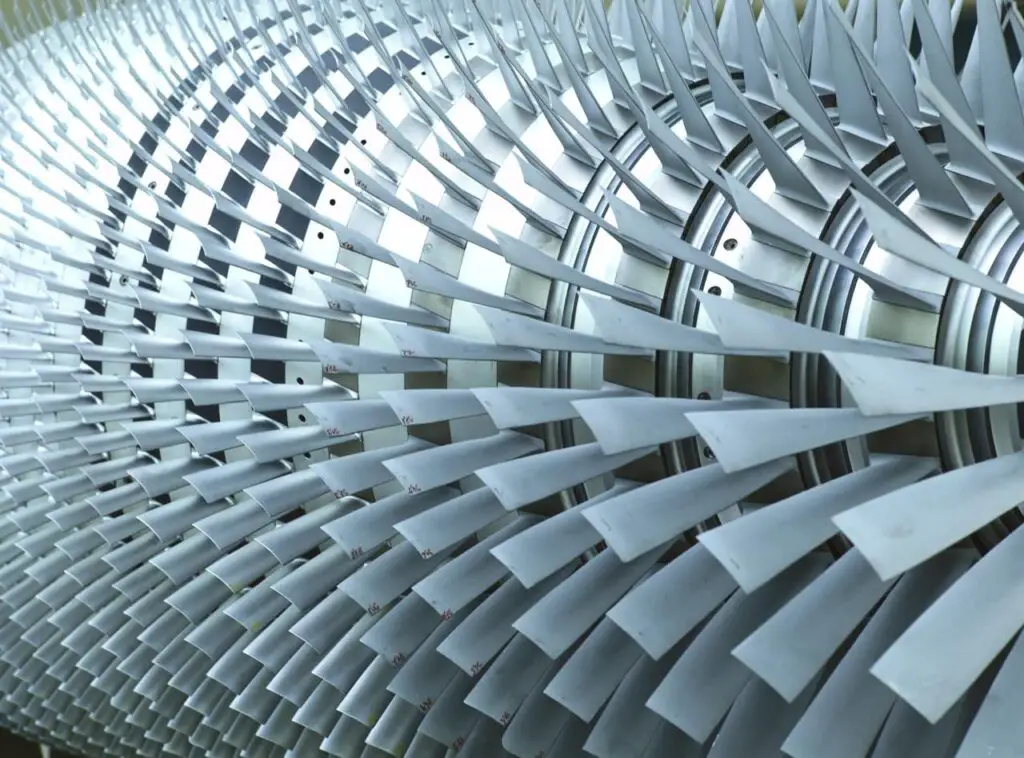

- Used To Make Rotary Machines

Grades Of Stainless Steel

There Are the Following Grades Series

300 Grades Series Of Stainless Steel

There Are Different Types Of 300-Grade Stainless Steel.

303 Stainless Steel

Because it has a lot of sulfur and phosphorus, 303 stainless steel is easy to work with. It is often used to make bolts, nuts, gears, and fittings in the aerospace industry.

304 And 304L Steel

The austenitic stainless steel that is used the most often is 304. 304L is a type that is different because it has less carbon in it. 304 is used in many fields, like the automotive, food and beverage, nuclear, and shipping industries, while 304L is mainly used for welding.

316 And 316L Stainless Steel

When compared to 304, 316 is used less often. This is because the alloy has more molybdenum and nickel and comes in a version with less carbon called 316L. In addition, because of how it is made, it is more resistant to corrosion, especially from chlorides like salt and seawater. As a result, 316 can be used in nuclear power plants and marine environments, while 316L is often used in the chemical and pharmaceutical industries.

321 and 321H Stainless Steel

Titanium is in both 321 and 321H. But 321H has more carbon, which makes it more resistant to high temperatures. Both alloys are often used in places that make chemicals or refine oil and gas.

347and 347H Stainless Steel

347 and 347H have a higher amount of niobium and tantalum, which makes them suitable for welding. Both materials are often used to make car and plane parts and store chemicals.

400 Grades Series Of Stainless Steel

There Are Different Types Of 400-Grade Stainless Steel.

410 Stainless Steel

410 is strong and doesn’t get worn down quickly, but it is more likely to rust and corrode when exposed to chemicals. The material is often used to make auto parts, medical products, nozzles, pipelines, and valves.

416 Stainless Steel

416 has sulfur in it, which makes it easier to work with. Because of this, it can be used in a wide range of products, such as valves, pumps, studs, gears, and parts for washing machines.

440C Stainless Steel

440C is very hard and doesn’t wear down quickly because it has a lot of carbon. However, it doesn’t resist corrosion very well. So, this material can be used to make knives, surgical tools, nozzles, bearings, and other things that need to keep their shape when they are put under pressure.

Stainless Steel Mechanical Properties

There Are the Following Mechanical Properties Of Stainless Steel

Yield strength

Stainless steel can have high strength and low elongation or low strength and high elongation, depending on the grade. However, when it comes to yield power, they are very similar to carbon steel.

Strength at high temperatures

At higher temperatures, stainless steel works better than most other carbon steel. However, it is less likely to catch fire because it keeps its strength well at high temperatures (above 500°C). Above 300°C, it also retains its stiffness better than carbon steel.

Tensile strength

Aluminium, brass, and mild steel are not as strong as stainless steel regarding tensile strength.

Precipitation-hardening and martensitic grades have the highest tensile strength. The tensile strength of these grades can be twice as high as those of the standard 304 and 316 degrees. As a result, duplex steel has a high power ratio to flexibility.

Cryogenic resistance

Some types of stainless steel can handle a wide range of temperatures very well. For example, austenitic steels are tough and have higher tensile strength at temperatures below zero. This makes them much more helpful and opens up new ways to use them in the modern world.

On the other hand, ferrite, martensitic, and precipitation-hardening grades are not as good at cryogenic temperatures because their toughness drops as the temperature drops.

Ductility

Different grades of stainless steel can be very different in how easily they can be bent. However, some qualities are easy to bend so that they can be used for complicated deep drawing processes.

Higher work hardening rate

This property describes a metal’s ability to get stronger through cold working. For example, you can change the strength of stainless steel by annealing it and working it while it’s hard.

This means that the same grade can be used for more than one purpose by changing how strong it is. The exact grade can be used as a spring or a wire that can be bent by annealing and cold working.

Electric conductivity and magnetism

As with all metals, electricity can flow through stainless steel. However, as with all steels, this conductivity is very low.

Stainless steel enclosures protect electrical equipment where hygiene standards are high, or the equipment may be exposed to corrosive or humid conditions.

Austenitic stainless steels are not magnetic, but some grades can be made magnetic through cold working. All of the other kids can be magnetized.

Stainless Steel Chemical Properties

There Are the Following Chemical Properties Of Stainless Steel,

High oxidation resistance

Because of this unique quality, stainless steel is used in many different ways in the business world. In addition, because stainless steel has chromium, it doesn’t rust easily. In some grades, chromium can reach up to 26%.

Other metals may have coatings or paints that keep them from rusting, but once they wear off, the rusting starts. In the case of stainless steel, any damage to the surface that removes the natural coating of chromium oxide is followed by the formation of a new layer on the exposed surface, which stops corrosion from causing the steel to get worse.

Biologically inert

Stainless steel doesn’t react with living things, so using it for surgical tools, trauma screws, and plates makes sense. Because of this, it is also an excellent metal for making cutlery and kitchen appliances.

Resistance to acids, bases, and organic materials

Stainless steel can stand up to a lot of different things. It can’t be broken down by acids, bases, or organic compounds. Different grades vary in how well they stand up to acids. Some qualities can stand up to powerful acids, while others may only be able to handle low concentrations.

Both essential compounds and organic compounds don’t react with each other in the same way. Because of this, stainless steel is an excellent material for storing, moving, and other processes in the chemical industry.

Stainless steel doesn’t react badly with water, salt, sulfur, carbon dioxide, or chloride compounds. This makes it more robust than most other metals and helps it stay alive longer in harsh environments.

Conclusion

But it’s not true that it won’t get dirty. First, the grade affects how resistant it is to corrosion. But strange things in the environment, like low oxygen, poor circulation, and high salinity, can stain it in a way that can’t be taken off.

Stainless steel is a miracle material that hugely positively affects the industry, despite the abovementioned risks. Because there are so many grades with different properties, there is always a perfect grade for an application. To ensure your investment is of good value, you must choose the quality carefully.

FAQS

Which type of stainless steel is best?

The 304 stainless steel is the most common type of stainless steel used worldwide because it resists corrosion well and is a good value. 304 is resistant to corrosion from most oxidizing acids. Because it is so strong, 304 is easy to clean, making it perfect for kitchens and food-related applications.

What is the cheapest stainless steel?

Type 409 is one of the less expensive types of stainless steel because it has less chromium. This type should only be used for parts inside or outside corrosive environments that are not critical. For example, one everyday use is for making muffler stock.

Can stainless steel rust?

Because its alloying elements interact with the environment, stainless steel stays stainless or doesn’t rust. Stainless steel has iron, chromium, manganese, silicon, carbon, and, in many cases, large amounts of nickel and molybdenum, which makes it rustless.