What is Turbine?

A turbine is a mechanical rotating device that converts fluid potential and kinetic energy into mechanical energy. It is a primary mover that converts the working fluid’s energy into the mechanical energy of the turbine shaft. The shaft is then used to drive other mechanisms using reduction gears to get useful work done.

What are the Main Components of a Turbine?

The main components of a turbine are as follows:

i) Nozzle: It directs the flow of steam, water, or other fluids in a predetermined direction and at a predetermined speed.

ii) Runner: The runner is the component of the turbine that spins, and the blades are mounted to it.

iii) Blades: The part of the turbine where the quickly moving fluid collides with the runner to cause rotation.

iv) Casing: The turbine’s outer airtight covering is the runner and blades. It safeguards the turbine’s interior components.

How does a Turbine Work?

A turbine’s operation concept is that the blades begin moving to generate spinning energy as soon as any liquid enters the turbine’s rotor or impeller. Generators directly connect the turbine’s rotor shaft with its output shaft to convert mechanical energy into electricity. A turbine’s rotor and blades harvest energy from moving fluids. The turbine’s efficiency depends on the blade design. The blade design is therefore critical to the turbine’s efficiency.

What are the Different Types of Turbines?

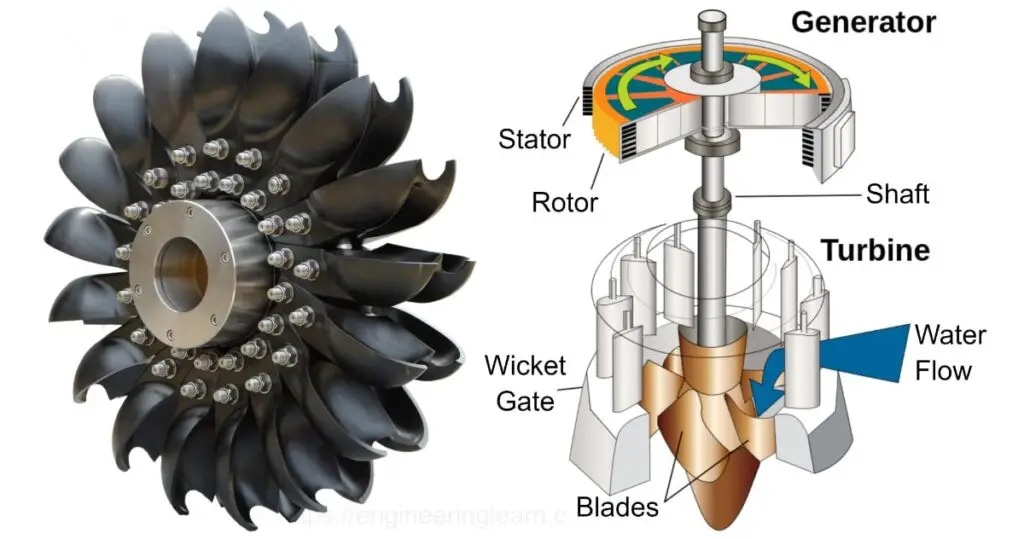

1. Water Turbine:

Fig 1: Water Turbine

Courtesy: engineeringlearn.com

Water turbines are the turbines found in hydroelectric power facilities. A water turbine can be installed after a huge pipe called a penstock. The dam’s height has a major impact on the water pressure in this case, as the higher the dam, the greater the pressure.

As soon as the turbine is installed at the end of the pipe, significant water pressure will contact the blades and cause the turbine to spin. Directly linked to a generator is this water turbine. An electrical generator will transform mechanical energy from a water turbine into electricity as soon as they start spinning. The water’s force and velocity heavily influence the shape of the turbine blades.

Water turbines are classified into two types:

i) Impulse Type Turbine:

Courtesy: engihub.com

In these turbines, the static pressure in the runner remains constant, and the turbine runner is at atmospheric pressure. Fluid is sprayed on the blades of the spinning runner to exchange energy with the turbine. Jet nozzles or a series of nozzles direct the high-speed flow to the blades, which are often shaped like buckets or cups. Because of this, only pressure changes take place in the nozzles. The purpose of the curved blades is to alter the flow rate.

Due to the law of energy conversion, the strike forces the turbine blades. Newton’s second rule of motion states that the force generated by fluid motion depends on two factors: the mass of the fluid entering the turbine and the changes in fluid velocity between the turbine inlet and outlet. Since there is no change in fluid mass, only velocity changes are considered when computing a runner’s force.

ii) Reaction Type Turbine:

Courtesy: studentlesson.com

A reaction turbine’s torque is generated by reacting to fluid pressure or weight. According to Newton’s third law of motion, the operation of reaction turbines can be explained (action and reaction are equal and opposite). Reaction turbine nozzles are attached to the rotor, unlike impulse turbines.

When the fluid exits the nozzle at high speed, the pipes generate a reaction force that causes the rotor to move in the opposite direction as the fluid. It’s important to note that the flow of fluid is affected by rotor blades as it passes through them.

When working with water, a pressure casement is required to keep the suction from the draught tube in place and the working fluid from escaping. Instead, in the absence of a casing, a turbine must be completely submerged in a fluid flow, as is the case with wind turbines. Two main types of steam turbines use reaction turbines are Francis Turbine and Kaplan Turbine

2. Wind Turbine:

Courtesy: udel.edu

Wind energy can be converted to electrical energy using a wind turbine. These turbines are available in various sizes, with either vertical or horizontal axes. Wind turbines are environmentally friendly, sustainable, and inexpensive.

The rotor of this turbine is made up of three separate parts. When the blades are in contact with the air, they begin to spin. Smaller wind turbines are primarily used for charging the batteries of caravans, boats, and traffic warning signs.

Wind turbines use the aerodynamic force of the rotor blades, which work like airplane wings or helicopter rotor blades, to convert wind energy into electricity. One side of the blade experiences a drop in air pressure due to the wind. Lift and drag are caused by the blade’s asymmetrical air pressure distribution. The lift force is larger than the drag force, which causes the rotor to spin.

The rotor is attached to the generator in a direct-drive turbine or gearbox, allowing for a smaller and more compact generator. Aerodynamic force is converted into rotational motion in an electric motor to generate electricity.

There are two types of wind turbines- i) horizontal axis wind turbine and ii) vertical axis wind turbine.

i) Horizontal Axis Wind Turbine:

Courtesy: archiexpo.com

Wind turbines with a fixed horizontal main shaft distinguish themselves from those that rotate vertically in the sky. As the name suggests, the horizontal wind turbine’s axis of rotation is located horizontally to the ground. Large horizontal axis wind turbines produce most of the world’s wind power with three blades surrounding the tower.

These turbine towers have generator and rotor shafts that must face the wind in the opposite direction. From 100W to 100KW, horizontal axis wind turbines can be found in various capacities. Typically, these are positioned in windy conditions where the flow and direction of the wind are stable enough to maximize the wind power they can generate.

ii) Vertical Axis Wind Turbine:

Wind turbines with vertical axis blades are the most well-known and widely used type. Perpendicular to the ground, the vertical-axis wind turbine’s main shaft is permanently attached. Additionally, the turbine’s bottom contains several crucial components. The axis of rotation of a vertical axis wind turbine is parallel to the ground.

The turbine does not need to be turned in the wind direction to work effectively. In these turbines, the primary gearbox and gearbox can be located closer to the ground, allowing easier maintenance. This type of wind turbine has significantly more worn-out transmission gearbox components than horizontal axis wind turbines.

On the other hand, this type of wind turbine has a significant drawback: it produces less energy on average than horizontal axis wind turbines. The vertical axis wind turbines are specifically designed to be cost-effective, practical, efficient, and quiet. It is why they are so popular. Residents can put these wind turbines to good use in their own homes.

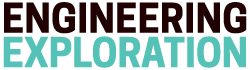

3. Steam Turbine:

Courtesy: ge.com

In a steam turbine, the thermal energy of steam is converted into mechanical work. A steam turbine’s construction is extremely straightforward. The turbine lacks a piston rod, flywheel, or slide valves. As a result, it’s a breeze to maintain.

While rotating, a shaft is attached to the center of the rotor, which generates thrust while the entire unit is in motion. The rotor shaft is connected to a steam turbine generator, an electric generator. The turbine generator captures and transforms the shaft’s mechanical energy into electrical energy.

The efficiency of the steam turbine generator can also be improved by using a steam turbine. Using a steam turbine relies on steam’s dynamic action to do its work. The high-velocity steam from the nozzles hits the rotating blades on a disc mounted on a shaft, causing them to rotate.

Dynamic pressure on the blades is created due to this fast steam, causing the shaft and blades to rotate in the same direction. At its core, pressure energy extracted from steam is converted into kinetic energy by allowing it to flow through the nozzles in a turbine.

A steam turbine generator acts as a mediator between the rotor and the blades of the rotor, converting kinetic energy into mechanical work for them. Electrical energy is generated by turning the rotor into mechanical energy and then converting it. There is less vibration in a steam turbine at the same rotational speed because of its simple design. A variety of governing systems are employed to increase the turbine’s speed.

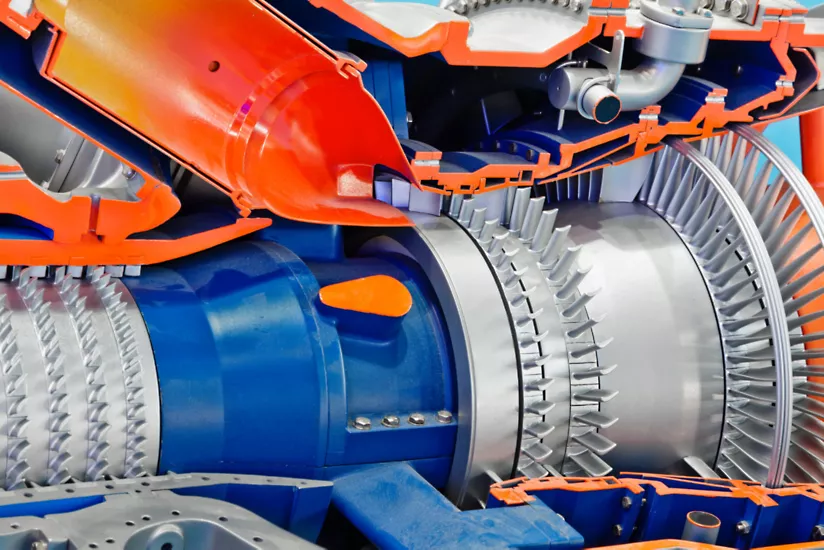

4. Gas Turbine:

Courtesy: ansys.com

The process is known as a Brayton cycle when pressurized gas is used to rotate a gas turbine to generate electricity or provide kinetic energy for a plane or jet. When using a modern gas turbine, the fuel can be kerosene, natural gas, jet fuel, or propane to generate the gas. Fuel combustion produces heat, which expands air and powers the gas turbine, generating useful energy.

Compressor, combustor, turbine, gearbox, output shaft, and exhaust are all included in these turbines. The compressor begins by compressing and utilizing ambient air. Fuel is ignited in a combustor by combining it with air.

During the expansion, the turbine converts the kinetic energy of high-rate gas into rotary force. The turbine section’s low-emission gas is routed through the gearbox and output shaft, which supplies rotating energy to the driven machinery.

What are the Pros and Cons of Turbines?

The pros of different types of turbines are as follows:

- Water turbines have many pros, including the fact that it is a clean and non-polluting source of energy, that it doesn’t require fuel, and that water is a source of energy.

- Energy generated by wind turbines is clean and renewable, and it is also less expensive to operate and takes up less land than other types of energy generation.

- The pros of steam turbines include their high reliability, low vibration, low mass flow requirements, high power-to-weight ratio, and high thermal efficiency, to name a few of their many attributes.

- Among the many pros of gas turbines are their long service life, low maintenance requirements, energy efficiency, low noise, and low environmental impact.

The cons of different types of turbines are as follows:

- Water turbines have several cons, including little reservoirs, high costs, the displacement of people, and environmental impacts.

- There are many cons to using a steam turbine, such as a long startup time, a high cost, and a slow response time.

- The pros of a wind turbine include that it produces a lot of noise, impacts the environment, can only be placed in certain places, is intermittent, and so on.

- Gas turbines have many pros, including lower plant efficiency and limited use in combined cycle configurations.

What are the Applications of Turbines?

- Hydroelectric power plants use water turbines.

- High-head hydroelectric power plants commonly employ an impulse turbine.

- Electricity is generated using a reaction-type turbine in wind power plants.

- Wind turbines can be found in places where the wind is consistent and strong, such as on rounded hills, along the coast, on open plains, and in mountain gaps, while large wind turbines can provide 100 kW to MW of power to the grid.

- Steam turbines are used in various medium- to large-scale industries, including chemical plants, waste treatment facilities, and oil, gas, and sugar mills.

- A gas turbine is an internal combustion engine that generates electricity in power plants and powers aircraft and helicopters.

Conclusion:

The turbine is a mechanical device that converts the energy of steam, flowing water, wind, and gas into mechanical energy to power an electric generator. The energy is then converted from mechanical to electrical by this generator. This combination is known as a generating unit in hydroelectric power plants.

Various types of turbines are classified based on various factors. Turbine and rotor efficiency research are still ongoing due to the turbine’s many applications in various technologies.

FAQ:

1. What is the purpose of a turbine?

A turbine’s primary purpose is to turn the available energy into the fluid that enters it to generate electrical energy. At the time of its conception, the turbine expanded fluids entering it, reducing their pressure—or even their internal power.

2. Why is high-pressure steam used in turbines?

A high-pressure turbine is extremely efficient and compact, but it requires steam at a high pressure to operate by forcing the steam to squeeze through nozzles. The turbine blades have been hit by high-velocity steam to generate rotation.

3. How can you increase the efficiency of a turbine?

Cooling the air entering a gas turbine can increase its efficiency. In warm, dry areas, this is very beneficial. By using evaporative cooling to get the inlet air to the temperature of a wet bulb, turbine air inlet cooling can significantly improve fuel efficiency by reducing (or even eliminating) fuel consumption.

4. Why are turbines more efficient at higher temperatures?

Temperature raises lead to higher cooling air requirements in air-cooled gas turbines. To increase the firing temperature without requiring substantial air cooling, closed-circuit steam cooling of gas turbines is ideal.

5. Which is the most efficient type of turbine?

Steam turbines are easier to repair because of their straightforward construction. Additionally, industrial steam turbines can achieve up to 90 percent efficiency. It means that steam turbines are the most efficient in most applications.