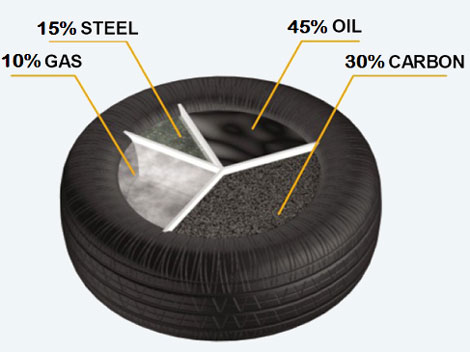

About 240 million tires are thrown away by Americans annually, about one per person. Most of these tires end up in landfills. We also eliminate 1.3 million gallons of used oil, about 5 gallons per person.

About 30% of this goes into landfills, on the ground, or down sewers. In addition to hurting the environment, this is a massive waste of resources. For example, a standard tire has the same amount of energy in British thermal units (Btu) as two and a half gallons of gasoline. Through the tire liquefaction process, scrap tires and used oil are turned into energy sources to be used (see chart).

The Process of Producing Energy

In Texaco’s tire liquefaction process, pieces of shredded tires are mixed with hot oil in a liquefaction reactor. Since the temperature isn’t too high—less than 700°F—this method is more like a mild cracking process than pyrolysis, which is another way to recycle tires. Two liquids are made: a light condensate oil and a heavy tire oil similar to fuel oil. The light condensate oils can be refined into gasoline, diesel, heating fuel, and other chemicals.

The process makes a small amount of Btu gas, which is used to heat the process heaters in the reactor. A screen keeps steel and fiberglass belting out of the tire oil. After a high-temperature cooking unit removes any oil coating, the steel is sent to a metals reclaimer. When the carbon black is mixed with the tire oil, it can be used as a fuel or part of making asphalt.

Uses of Tire Oils

Tire oil can be used for different things, depending on the market. It can be distilled in the same way waste oils are now used to make base lube oil stocks and fuel for boats or heaters.

The rest of the parts can be used to make asphalt, or if none of the other options are cost-effective, most tire oil can be turned directly into the asphalt. The oil from the tires can also be cleaned up like crude oil. But there is a question about metals in tire oil that could damage equipment at refineries.

Texaco could also feed the Texaco gasification process a mixture of water and oil from old tires. In the 1950s, the Company made gasification technology to make chemicals and fertilizers. Since then, the number of uses has grown, and along with the 100 licenses sold, Texaco now has 40 gasifiers in use.

The gasifier is a cylinder lined with refractory materials to keep the steel shell from getting too hot during the gasification process, which happens at 2,500°F. In slurry form, the gasifier is fed raw materials like coal, industrial waste, refinery tank sludge, plastics, contaminated soil, hazardous waste, Orimulsion (tar deposits from the Orinoco), and tar oils.

Oxygen is also sent to the gasifier. Synthesis gas, or syngas, is made by the gasifier. It is mostly hydrogen and carbon monoxide, with some carbon dioxide and methane. Syngas is very clean, similar to natural gas, in that all the particles have been removed.

During gasification, sulfur is recovered as a byproduct, and high temperatures destroy all organics. After the syngas is turned into slag, metals are trapped in the slag.

Syngas can be used instead of natural gas in a combined-cycle system for making electricity. The system has a gas turbine that works like a jet engine and a steam turbine that works like a steam engine. Both are connected to their electric generators. First, the gas turbine burns syngas to make hot exhaust gases. Then, the hot exhaust gases boil water to make steam, which turns the turbine.

Production capacity of the Company

Texaco can build Texaco tire liquefaction systems in modular units that can handle 2,000 tires per day and take up less than an acre of space. This system will cost about $2 million. Even though a 2,000-tire-per-day unit is the smallest size that can make money, it could be expanded in steps of 2,000 tires, up to a maximum of 10,000 tires, with an incremental investment cost of 50 to 60 percent. Ten people would work at a 2,000-tire unit; one tank truck could remove the tire oil made daily.

Texaco says that a gasification unit probably wouldn’t be worth the cost if all it did were turn tires into liquid. For the gasifier to be cost-effective, it would need to be fed other things, like waste, oil, and coal.