Engineers from the University of Sheffield are developing a new method to produce green hydrogen gas. It is known as the water-powered fuel cell, which can extract hydrogen gas from water by using sound waves to increase production.

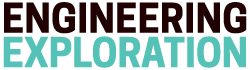

The device uses energy harvested from waves on an artificial lake to generate electricity and break down water molecules into oxygen and hydrogen. This method could boost green hydrogen production by up to 14 times, making it a valuable breakthrough.

It’s not just clean and affordable, but this method also doesn’t require any input of resources other than wind or solar power, which means it has zero emissions!

How is green hydrogen made through electrolysis?

Two electrodes run electricity through water and split water molecules into oxygen and hydrogen gases. This process makes green hydrogen, but because it takes a lot of energy, it only makes up a “small fraction” of the world’s hydrogen production.

However, the question now is: how can we produce the most hydrogen? The process of splitting blue hydrogen is another term for natural gas. Natural gas combustion releases greenhouse gases into the atmosphere.

The RMIT engineers successfully “split and conquered” individual water molecules using high-frequency vibrations in their experiment.

Electrolysis that included sound waves produced about 14 times more electricity than electrolysis that did not include them for a given input voltage. This was the same as how much hydrogen was made, “Yemima Ehrnst, the first author, said.

The discovery makes a big step toward using the “new acoustic platform”

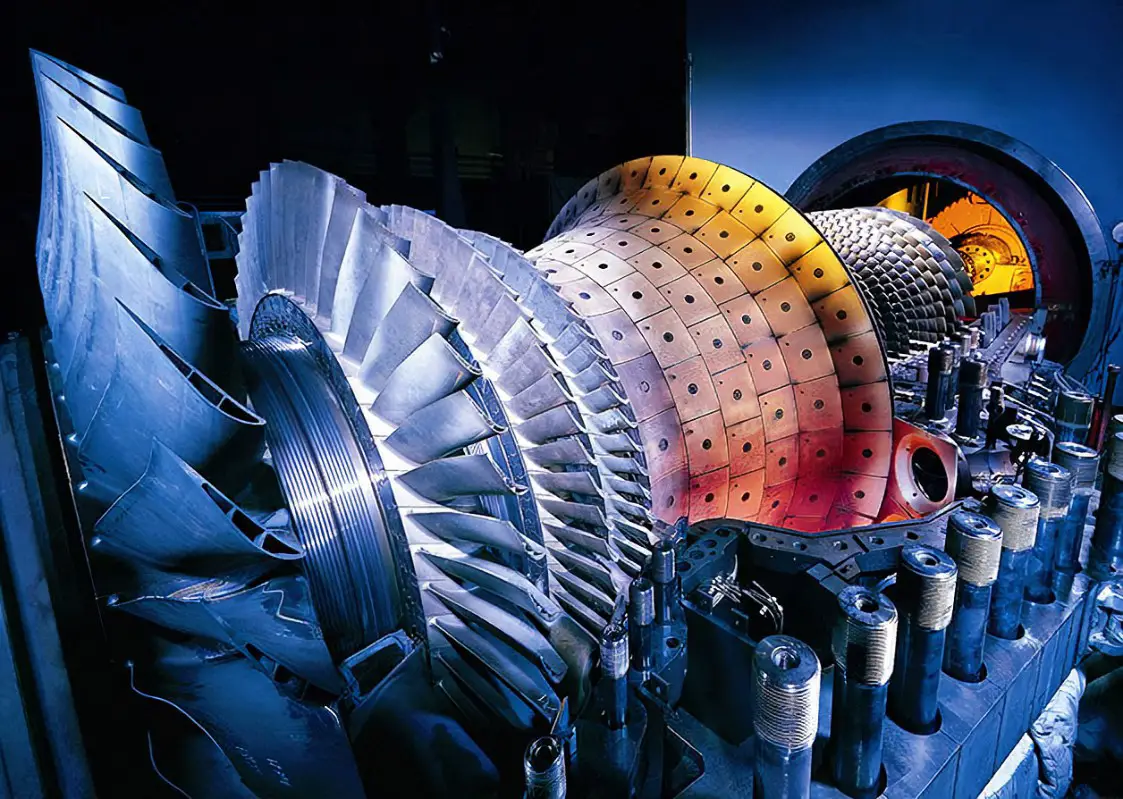

Ehrnst also said that the sound waves “stopped hydrogen and oxygen bubbles from building up on the electrodes, which made the battery much more stable and conductive.”

Electrolysis results in the buildup of hydrogen and oxygen gas on the electrode materials that are employed in the process, according to Ehrnst, a Ph.D. researcher from the School of Engineering at RMIT. This forms a gas layer that reduces the electrodes’ activity and makes them much less effective.”

One of the senior researchers, Professor Leslie Yeo, said that the breakthrough was a big step toward using the “new acoustic platform” for other things.

“Our ability to stop bubbles from forming on the electrodes and quickly get rid of them with high-frequency vibrations is a big step forward for the stability and conductivity of the electrodes. With our method, we might be able to improve the efficiency of the conversion, which could save 27 percent of energy overall “Yeo from the School of Engineering at RMIT said.

But to scale up the work, the team needs to figure out how to combine the sound-wave innovation with the electrolyzers they already have.

Research Abstract:

An innovative approach that modifies the network coordination state of neutral electrolytes and uses high-frequency hybrid sound waves with a frequency of 10 MHz is described as a way to boost hydrogen evolution processes (HER) significantly. These electrolytes are notoriously difficult to deal with. By redefining theoretically weak hydrogen electrocatalysts in neutral electrolytes, this article addresses the practical constraints associated with conventional electrolyzer technology.

These drawbacks include the need for extremely corrosive electrolytes and costly electrocatalysts. The unique capacity of strong local electromechanical coupling resulting from acoustic pushing to “frustrate” the tetrahedrally-coordinated hydrogen bond network of water molecules at the electrode-electrolyte interface is responsible for the improvement in HER performance.

This generates a high concentration of “free” water molecules that can more readily access catalytic sites on the unmodified polycrystalline electrode.

This electrode potential reduction of 1.4 V at 100 mA cm2 and a corresponding 14-fold increase in current density, along with a net-positive energy savings of 27.3%, demonstrates the potential of the acoustic excitation alone. Other synergistic effects accompanying acoustic excitation include the generation of hydronium ions, the convective relaxation of diffusion mass transfer limitations, and the prevention of bubble build-up and their removal from the electrode.