According to a recent study, ceramics can bend like metal.

Chinese scientists have developed the first ceramic material that can flex like metal. If correct, this research could enhance the functionality of artificial joints and engines.

Before this discovery, it was widely accepted that a ceramic’s flexibility and strength were mutually exclusive and that if one improved, the other would deteriorate.

The novel material is the first time that strength and lightness have been combined, according to the study’s principal investigator, materials scientist Chen Kexin.

Professor Chen’s Statement

Professor Chen from the National Natural Science Foundation of China’s engineering and material sciences department claimed that “this ceramic can bring technical revolutions to numerous industries.”

In the journal Science, Chen and colleagues from Tsinghua University reported their findings on October 27. In an editorial that appeared in the same edition of Science, Erkka Frankberg of Tampere University in Finland stated that the discovery “may result in materials that are more lightweight and durable than even the finest metal alloys of today.”

“Since I began my profession 30 years ago, there has been researching on the flexibility of ceramics worldwide. On that subject, one could say that we have finally made progress today,” Chen remarked.

The New Ceramic is Flexible Thanks to Nanotechnology

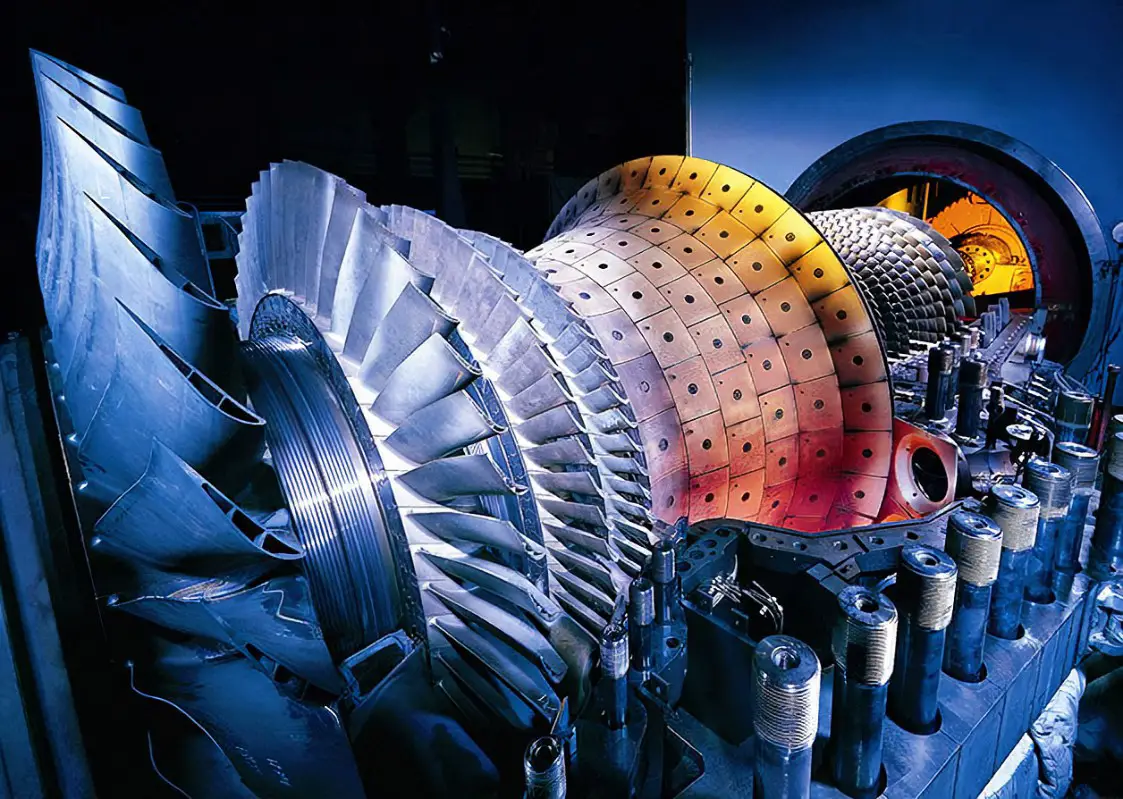

As it would be lighter than an alloy engine, a ceramic machine might move considerably more quickly. Lightening the engine relieves pressure on other parts.

The chemical could be used in automobile engines. Due to ceramic materials’ higher heat resistance to alloys, a ceramic machine may have a smaller coolant tank. Higher combustion temperatures in a ceramic engine could result in more thrust and fewer pollutants.

Previously, plasticity and strength were considered opposed properties of ceramics; an increase in one usually meant a decrease in the other. The study’s principal investigator, materials scientist Chen Kexin, claims that the new material is the first instance of scientists improving both simultaneously. It has the rigidity of ceramic and the flexibility of metal.

Metals used to Make Ceramic Flexible

Using silicon nitride, the researchers made nanopillars with two distinct crystal forms. When subjected to an external force, one crystal structure can transform into a different type. As a result, the material can bend before returning to its former shape.

He used the pricey rare earth minerals utilized to produce the single-crystal turbine blades seen in jet engines as an illustration. On the other hand, the priciest silicon nitride costs about $200 per kilogram.

“Based on our existing research, we will continue to improve this ceramic material. “Once a door is opened, a vast world is left behind,” stated Chen.

The Scientist stated facts about the Durability of Bendamic Ceramic

According to Chen, the substance might be utilized to create bearings, which are crucial components of wind turbines that connect the generator to the fan blades. The system’s overall service life is influenced by each bearing’s durability, which must withstand many tonnes of pressure while in use.

“Our adaptable silicon nitride ceramics could be utilised to create bearings with longer lifespans, lowering wind energy’s average cost.”

“Based on our existing research, we will continue to improve this ceramic material. “Once a door is opened, a vast world is left behind,” stated Chen.

According to Chen, the substance might be utilized to create bearings, which are crucial components of wind turbines that connect the generator to the fan blades. The system’s overall service life is influenced by each bearing’s durability, which must withstand many tonnes of pressure while in use.

The average cost of wind power could be reduced by using Chen’s flexible silicon nitride ceramics to create more extended bearings. Our experiments make it possible to manufacture this flexible ceramic material on a big scale. He continued that there is an absolute pricing advantage in high-end equipment.

The study is available for you to see in the journal Science.

Study Summary:

Due to their exceptional mechanical flexibility, high-temperature tolerance, and outstanding chemical stability, flexible ceramic fibres (FCFs) have been created for various sophisticated applications.

“Covalently bonded ceramics have outstanding qualities such hardness, strength, chemical inertness, and resistance to heat and corrosion, but their more comprehensive application is complex due to their brittleness at ambient temperature.

The atoms in covalently bonded ceramics require bond breaking due to the firm and directional nature of covalent bonds, as opposed to the particles in metals, which can slide along slip planes to accommodate strains.

Eventually, this results in a catastrophic failure during loading. We outline a method for creating covalently bonded deformable silicon nitride (Si3N4) ceramics with dual phases and coherent interfaces.

At the coherent interfaces, successive bond switching is achieved, allowing for a stress-induced phase transformation that eventually results in plastic deformability.”

Due to their exceptional mechanical flexibility, high-temperature tolerance, and outstanding chemical stability, flexible ceramic fibres (FCFs) have been created for various sophisticated applications.