We all are aware of Chinese engineering, their mastery of architecture, and their bewildering variety of bridges around the nation. In 2013, the Belt and Road Initiative was established. China proved that it is the Silk Road tradition’s heir. Seventy nations are connected by land and maritime routes included in the initiative.

But have you ever considered how they managed this project in a much shorter time while spending less money and using fewer resources?

Engineers are needed, but China also has a cool trick. The bridge-building device known as the SLJ900/32, also known as the “Iron Monster,” was created by the Beijing Wowjoint Machinery Company and designed by the Shijiazhuang Railway Design Institute.

All About the “Iron Monster”

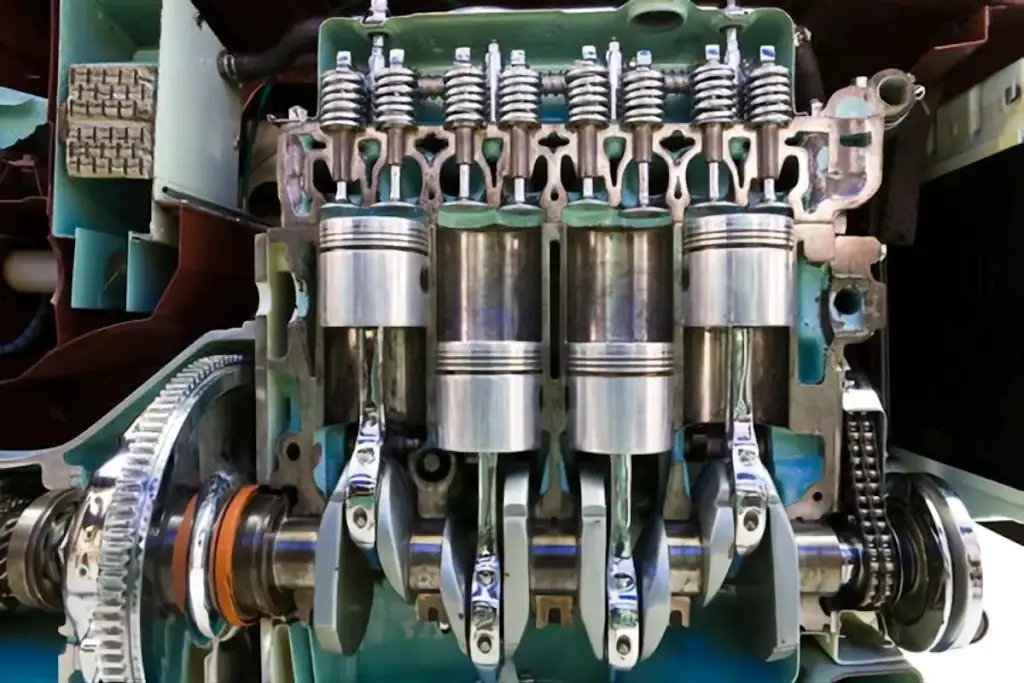

This enormous 680-ton machine automates the construction of bridges, resulting in time and cost savings. At 3.1 mph (5.0 km/h), it lifts, carries, and constructs prefabricated and full-length track sections, eliminating the need for on-site construction.

The Belt and Road Initiative, which links Asia, Africa, and Europe, was started by China as a result of the Silk Road’s transformation of that nation into a geo-economic power. While the Maritime Silk Road links China’s coasts to Europe, the Silk Road Economic Belt connects land-based East Asia, South Asia, Central Asia, Russia, and Europe.

As a result, Iron Monster was developed as a marine and terrestrial network to link three continents. One example of SLJ900/32 is the Yibin Jinsha River Railway Bridge, the world’s longest road-rail steel arch bridge project. The 12-hour trip between the regions of Sichuan and Guizhou has been shortened to three hours, thanks to Yibin. The high-speed rail project connecting Inner Mongolia to the rest of China is another real-life case study.

Invention’s Importance Among Chinese Engineers

These innovations are still very significant in building engineering, despite the claims made by critics that this initiative forces Chinese debts on less developed nations, establishing the Chinese World Order. The SLJ900/32 is a large bridge construction machine produced by the Beijing Wow Joint Machinery Company and designed by the Shijiazhuang Railway Institute.

The longest road-rail steel arch bridge project in the world, the Yibin Jinsha River Railway Bridge, is one of the real-world applications of SLJ900/32. The expected travel time between the Chinese provinces of Sichuan and Guizhou has decreased from 12 hours to three hours after the construction of the Yibin Jinsha. Another illustration of a high-speed rail project is the one that connects Inner Mongolia with the rest of the nation as part of China’s plan for a 30,000 km (18,641.1 mi) high-speed rail.

The 64 fully revolving wheels separated into 4 blocks move the bridge girdling machine. It carries the beams from the very edge of the bridge to the installation place, where it will be joined to a preset pillar, where the building begins. The machine is then attached to the first pillar using a pneumatic structure, extending to the second, anchoring it, and placing the beam. Next, SLJ900/32 performs identical procedures while towing the new segment.

Still, Improvement is Required in “Iron Monster”

Even because Iron Monster uses a lot less labor than crane-based bridge construction, the staff is still needed to oversee the entire operation and clean and maintain its numerous components. The crew’s work begins as soon as the machine sets the segment, and the process is repeated until the bridge is finished.

Due to the machine’s efficient use of labor, lack of the need for pricey scaffolding, and faster project completion, it has proven effective, especially in larger building projects like the Belt and Road. Additionally, because of its 640-ton (580 tonnes) weight, the bridges must support more weight than they were designed to, which is considered an unexpected bonus and increases the safety of the bridges built with this equipment.

Unfortunately, to construct these machines, redoing of resources and technology is required every four years because they only have a lifespan of roughly four years and can only lay 700 to 1,000 bridge spans or the distance between two intermediate supports for a bridge.