If you’re one of those people who use a screwdriver to take apart everything around them — from appliances to electronics, to cars and water pipes, for example — you might be interested in knowing more about the different types of screws and how they’re used in other areas of the construction world.

A screw is a simple tool to create holes in wood, plastic, metal, glass, and many other materials. Screws have been around since ancient times and were initially used to fasten two pieces of wood together.

Today, screws are widely used in construction, manufacturing, carpentry, plumbing, electronics, and many other industries. There are several different types of screws, including drywall screws, lag screws, machine screws, sheet metal screws, and self-tapping screws.

In this article, we will first discuss parts of screws and some common types of screws and then offer context on how they are used in construction.

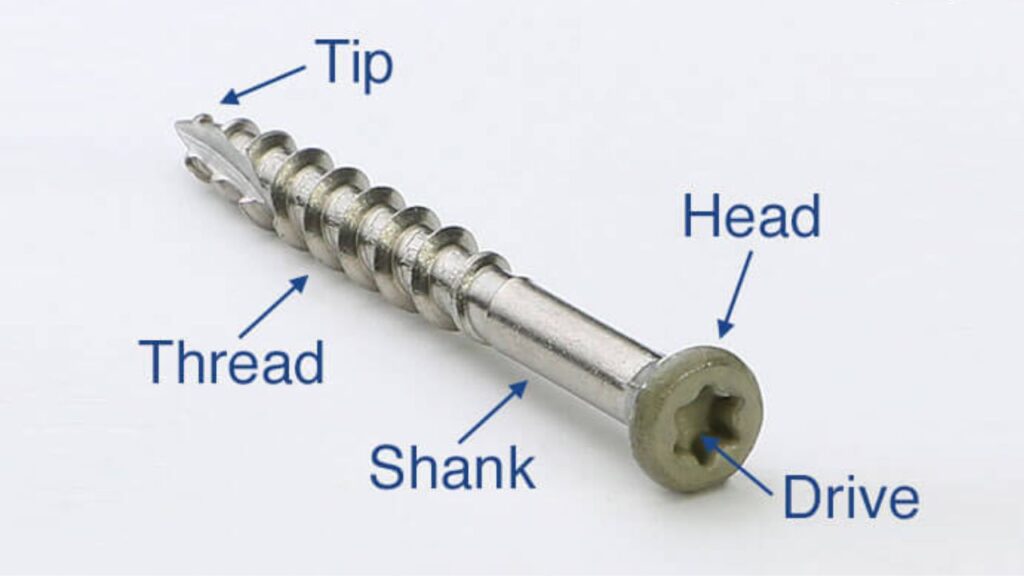

Parts Of Screws

There are the following parts of screws.

- Head

- Drive

- Threaded shank

- Non-threaded Shank

- Tip

- Crest

Head

A head of screws is the portion of a screw that extends beyond the shaft of the screw. A screw’s head may have various shapes and sizes depending on its function. Screw heads are designed to hold fasteners (nuts) onto threaded shafts. Heads may be flat, domed, hexagonal, octagonal, square, triangular, or any combination.

Drive

The drive is the mechanism that turns the screw. There are two types of drives, internal and external. The rotation of the shaft powers internal drives. External drives use power supplied by an outside source.

Threaded shank

The threaded shank of a screw is the portion of the screw that goes inside the hole of the object being screwed together. The threads of the shank are designed to match the threads of the hole to ensure a tight fit. When the two parts are tightened together, they create friction between the threads of the shank and the threads of the hole. This friction creates pressure that causes the two pieces to become firmly attached.

Non-threaded Shank

A non-threaded shank is a type of screw that does not have threads on its shaft. These screws are commonly used in woodworking projects. A non-threaded shanked screw is a type of screw where the head is attached to the shaft using a flat surface instead of threads. Non-threaded shanks are often used in applications where threading would cause damage to the material being worked upon.

A thread of the screw is the portion of the screw that goes around the shaft of the screw. A thread of a screw is a spiral groove cut into the surface of the screw’s shaft. Threaded screws have a continuous spiral pattern of grooves along their length.

Tip

A tip of a screw is a small piece of metal that is attached to the end of a screw. A tip of the screw is designed to prevent the screw from being stripped out of the hole.

Crest

The crest of the screw is the point where the thread meets the shaft of the screw. Therefore, to have a good connection between the two parts, they need to meet at a specific angle called the crest of the screw.

Types Of Screws

There are the following types of screws

- Wood Screws

- Socket screws

- Masonry screws

- Deck screws

- Sheet metal screws

- lag screw

- self-drilling

- Hammer Drive Screws

- shoulder screw

- Carriage Screws

- Double-Ended Screws

- Eye Bolt Screws

- Fillister Head Screws

- Hex Cap Screws

- Particle Board Screws

- Washer-Faced Screws

Wood Screws – Types Of Screws

Wood screws are commonly used for woodworking projects. A wood screw is a fastener driven into wood using a drill bit. There are two types of wood screws, regular wood screws and drywall screws. Drywall screws are designed specifically for use in drywall applications.

Regular wood screws have a head and shank designed to fit a hole drilled into the wood. Drywall screws have a head and a shaft designed to fit directly into the wallboard. Both types of wood screws are made out of metal.

Socket screws – Types Of Screws

A socket screw is a fastener that uses a hexagonal head to connect two parts. These types of clasps are commonly used in woodworking. A standard socket screw has a flat top surface and a threaded hole at its center.

The threads allow the screw to be tightened onto a piece of material. The head of the screw is designed to fit over a matching hole in the mating part of the material. When the components are connected, the head of the screw fits snugly inside the hole.

Masonry screws – Types Of Screws

Masonry screws are commonly used in masonry work. These screws have a hexagonal head at the top and a flat washer-shaped shank below. They have been around since Roman times and were initially used to hold bricks together.

Deck screws – Types Of Screws

Deck screws are used to fasten wood together. They are commonly used to attach decking boards to the side rails of a deck. They are also used to attach decking boards to posts. These screws have two parts, a head and a shank. The head is the part that goes into the wood, and the shank is the part that holds the screw in place.

Sheet metal screws– Types Of Screws

Sheet metal screws are fasteners formed by rolling sheet metal over a mandrel. Sheet metal screws are used to fasten two pieces of sheet metal together. The screw head is designed to fit inside the hole of the first piece of metal, and then the second piece of metal is placed over the top of the first piece. Then the screw is tightened down until the two parts of the metal are firmly attached.

These fasteners are commonly used in construction projects, especially steel framing. In addition, sheet metal screws are often used in place of wood screws due to their durability and corrosion-resistant nature. they are mostly used in machinery works.

lag screw – Types Of Screws

A lag screw is a threaded fastener designed to resist rotating its axis. A lag screw is commonly used to secure two parts together, especially when they need to be held in place while being tightened.

The primary use of lag screws is to secure wood together. Lag screws are commonly used to hold pieces of lumber together while they dry. Lag screws are also used to attach metal parts to wood. For example, lag screws may join two boards or attach a board to a beam.

Socket Screws are a fastener designed to hold two pieces of material together while providing some grip between them. It consists of a threaded shaft with a hexagonal-shaped head at the end. The head provides a place where the screw can be tightened onto the connected material.

Socket screws are used in many different ways. One way they are used is to secure wood panels to a wall. Another use is to connect metal parts to wood. Socket screws are also used to attach metal pipes to wood.

self-drilling – Types Of Screws

A self-drilling screw is a type of fastener that is driven into wood using a power tool. A self-drilling screw works by having a helical thread at the end of the shaft. As the screw is rotated, the threads cut down into the wood until they reach the bottom of the hole. Once the threads reach the bottom of the wood, the screw becomes fully embedded into the wood.

Self-drilling screws are commonly used in construction projects. They are useful for attaching things together without having to drill holes first. If you want to attach something to a wall, you could just put the screw into it and then tighten it down.

Hammer Drive Screws – Types Of Screws

Hammer drive screws are commonly known as Phillips head screws. These screws have a flat head at the top and a conical point at the bottom. The conical end is designed to fit into a matching hole in fastened material. When a screw is driven into wood, metal, plastic, or any other material, the conical point of the screw is forced into the material until it reaches its maximum depth. Once the screw is fully inserted, the flat head of the screw comes into contact with the material’s surface.

Hammer drive screws are commonly used in construction projects and home improvement applications. Hammer drive screws are designed to be driven into wood or metal using a hammer.

shoulder screw – Types Of Screws

A shoulder screw is a type of fastener that resembles a bolt, but instead of being threaded at both ends, it only has threads on one end. The threading on the other end is called the shoulder. When installing a shoulder screw, you insert the screw into the material until the shoulder hits the surface. Then, you tighten the screw down onto the material.

Shoulder screws are used to hold down the top of the stem of the plant while it grows. They are used to keep the top of the plant off the ground, which helps prevent rot and disease.

Carriage Screws – Types Of Screws

Carriage screws are a type of screw used to attach metal to metal or wood to metal. It’s different from other screws because it has a shallow mushroom-shaped head and a shaft that’s rounded all the way.

The carriage screw is made with a dome-shaped head to keep it from coming loose from one side. The giant screw head also keeps the screw from pulling through the wood structure. Also, using a domed nut keeps the carriage bolt from being unlocked from the side that isn’t protected.

Double-Ended Screws – Types Of Screws

Double-sided screws are threaded fasteners used to make a joint that is usually underneath an object. They are used as two pieces of wood or as two parts that can move together. They have two pointed ends that can be put into the two surfaces to make a joint that can’t be seen.

These are headless screws with rotating threads on both ends. They can be woodless screws with device screws on both ends or a mixture of wood screws. Screws with two sides can be easily attached or taken off by the user, making them easy to use.

Eye Bolt Screws – Types Of Screws

An eye screw is a screw with an eye-shaped loop at one end and threads around the screw shank at the other end. Eye bolts are used to attach a secure eye to a structure or system, making it easy to tie ropes or cables.

These are very easily carried in the metal and provide stability and strength so that the object can be easily pulled or lifted with a rope. Eye bolts are commonly used as a connection point for anchoring, pulling, pushing, or lifting.

Fillister Head Screws – Types Of Screws

Filler head screws are slotted head screws. These pan heads are near machine screws but are made with larger heads that can be useful for connecting metal or wood to metal. They are often mostly referred to as cheese head screws as well.

The heads of these screws are essentially chosen for cylindrical holes. These oversized deep heads make them suitable for piston and spline drives. But more generally, cap screws are an excellent choice for tool-making and automotive applications.

Hex Cap Screws – Types Of Screws

Hex head screws are hexagonal screws (hexagons) made with a slotted hex head and a washer on the seating surface. These types of screws are used to connect wood or metal to wood. These screws have tight body dimension tolerances and are chamfered.

Hex screws have short steel threads, making them ideal for interior improvement projects. These screws also include a flat washer under the screw head to ensure precise application. Hex bolts are primarily used in docks, bridges, road structures, and buildings.

Particle Board Screws – Types Of Screws

Chipboard screws are full-thread screws. The benefit of these screws is that the longer thread provides greater engagement and pulling force. This type of screw is manufactured for composite wood, such as laminated chipboard or craft wood. And it is used by carpenters in both domestic and commercial joinery.

Particleboard screws are similar to drywall screws but are available in shorter lengths than standard drywall screws. Just because of their lightweight, they are easy to handle. Carpenters use these screws in both domestic and commercial joinery.

Washer-Faced Screws – Types Of Screws

These kinds of screws act as springs to reduce the distance between the nut and the screw head. Washer screws are available in many styles and sizes.

Some types have teeth that penetrate the surface and lock the screw head into the workpiece. With this type, the face of the washer is located just below the head, providing a smooth seating surface for easy tightening.

FAQS

How can you tell screw size?

To measure the size of the screw, First, you can measure the diameter of the head of the screw using a caliper. Then multiply that number by the number of threads per inch.

How can you tell the difference between screws?

The visible difference is in the thread. Wood screws have a more comprehensive, medium-deep screw. Some wood screws – the longer ones – often have a threadless shank at the top. Sheet metal screws always have a tighter, sharper thread that covers their entire length.

What is the most common screw size?

The most commonly used wood screws are numbers 6, 8, and 10. The larger the number, the greater the thickness. I almost always use #8 screws. Longer screws are usually #10s.